| SFM-1021 Sprayformed Cold Work Steel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Composition(%) | C | Si | Mn | Cr | Mo | V | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.55 | 0.60 | 0.40 | 11.80 | 0.85 | 1.05 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Steel Grade: | SFM-1021 (Similar grades:AISI D2 ESR,BÖHLER K110 ESR,JIS SKD10,DIN 1.2379,XW-41) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Delivery Status: | Soft-annealed ≤HB220,or ready-made tools,UT qualified. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

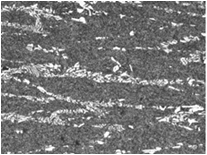

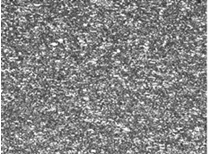

| Material feature:

| Super high solidification rate in sprayforming refines the carbide morphology from rough net-works to near-equiaxed,as can be seen from the pictures below,generating better machinability, more isotropic mechanical properties,e.g. impact toughness increases by 70 - 100%. That means usable hardness of the tools can be increased under the same toughness requirement,thus to reach much better wear resistance and tooling life than similar grade of ESR. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Applications: | For large,complex and heavy loaded wear resistant tools or parts,such as punching and trimming dies for alloyed steels,shearing blade,spinning die,stamping die,thread rolling dies and thread rolling plate,dies for cold heading,cold extrusion;crushing hammer,powder metallurgy &ceramics moulds;high wear resistance plastic mold,quality woodworking tools and hardware tools,high wear resistant measuring tools. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product sizes: | Round bar,up to DIA 300 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rectangular bar: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Microstructures: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Carbide morphology in DIA 200 mm bars,100x,D2 ESR (L),and SFM-1021 (R). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Remarks:Our expert,inventor of SFM Process,will technically support your applications to best benefits. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Company address: 18-A02 of 4th Xingye Road,Guanglong Industry Park,CN-528313 Foshan,China Tel./ Fax: 0757-23316070 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The above data are as reference,which is subject to change by SFM | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||